Recovering multipurpose lithium plastic metal-cladding grease MC 1000.

Contains a metal-cladding complex that regenerates friction surfaces and blocks corrosion, increasing the service life of components.

-

restores worn surfaces

-

metal-plating grease prolongs bearing life

-

operating temperature range: -40°C to+120°C (short-term+140°C)

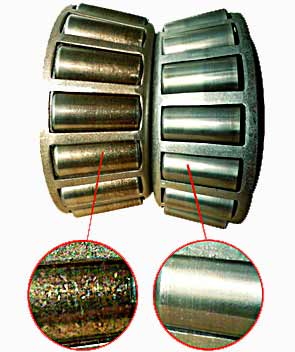

Illustration: left LITOL-24 , MS-1000 on the right

¦

¦

PROPERTIES:

-

penetration class NLGI-2/3;

-

compatible with lithium greases

-

significantly extends the service life of metal parts of bearings;

-

allows to increase the interval between grease changes;

-

eliminates the occurrence of scoring and welding of rubbing parts;

-

reduces noise caused by bearing wear;

-

successfully works in heavily loaded friction units;

-

successfully replaces all types of greases, general-purpose greases and some other greases.

APPLICATIONS:

-

hub bearings

-

vehicle chassis parts

-

gears

-

other loaded units

Metal-plated grease increases bearing life, saving money on parts, service and simple.

When the ball of the bearing rolls along the track, increased pressure and temperature are created in the contact zone. Thanks to them, the metal particles of the lubricant become part of the main part.

Increasing the load leads to the formation of the thinnest metal layer, which provides a minimally low coefficient of friction.

The forming metal protective film has high wear resistance and ability to permanent self-healing from grease components.

Classification according to DIN 51502/DIN 51825 KPF 2 N-40.

_____________________________________________________________________________________

Information on metal-clad lubricants

Metal-clad lubricants are greases, oils and cutting fluids containing metal-containing additives (powders of metals, their oxides, alloys, salts, complex and other compounds).

Metal-clad lubricants are one of the promising types of antifriction lubricants .

They are obtained by adding additives to liquid petroleum or synthetic oils along with thickeners (for example, salts of higher fatty acids, silica gel): powders soft metals, oxides, alloys, salts. Main areas of consumption: heavy-duty friction units in aviation and road transport, rolling mills and other metallurgical, as well as textile, sewing and footwear equipment.

Work on the creation of metal-cladding lubricants was preceded by studies (1930-40s) of the effect on the friction of metal rubbing pairs of plastic metal films applied to their surfaces by different technological methods.

Films formed when using metal-clad lubricants differ in structure from common metals, obtained, for example, by ore reduction or galvanically, which gives these films high antifriction properties.

For the first time in the world, metal-cladding lubricants began to be produced from the USSR. Lead 01 and Lead 22 greases were developed by order of the aviation industry. Currently, the range of greases has expanded. MS Vympel and MS-1000 have been added to the above mentioned brands.

The benefits of using metal-cladding lubricants (containing ultradispersed metal powders) have been known for a long time.

But they did not receive widespread use, apparently due to for a higher initial cost than universal greases. However, the economics of operating equipment suggests that these costs quickly pay off.

It is known that there should be a thin oil film between the rubbing pairs, but if the load, temperature slightly increased, water or microscopic dust got in, then the film collapses and dry friction begins.

Its effects are well known: pitting, scuffing, etc. To prevent this, anti-seize additives are introduced into ordinary oils - sulfur, phosphorus, chlorine compounds.

Interacting with the metal, they form a "soft" layer, which partially absorbs and prevents dry friction.

But this chemical reaction is irreversible, metal salts are easily removed from surfaces during their direct contact, contaminating the lubricant, and moreover, for a start, albeit at the molecular level, but the design clearance in the pair will increase, and given the long-term nature of the operation of the unit, in the end this can lead to a quite measurable increase in clearance.

Metal-clad grease is intended for all types of friction units:

-

Bearings

-

Crossings

-

Gears

-

Tie rod ends

-

Ball joints

-

Constant velocity joints (CV joints)

Advantages of metal-clad lubricants:

-

Significantly extends the service life of metal x parts

-

Extends grease change intervals

-

Eliminates scuffing and welding of rubbing parts

-

Reduces noise caused by bearing wear

-

Success works in heavily loaded friction units

-

Successfully replaces all types of greases, general-purpose greases and some other greases

So, the use of metal-cladding lubricants can significantly increase the durability of friction units, reduce frictional energy losses, and, consequently, increase the efficiency of machines and mechanisms, reduce the consumption of lubricants and increase the period between lubrication operations.